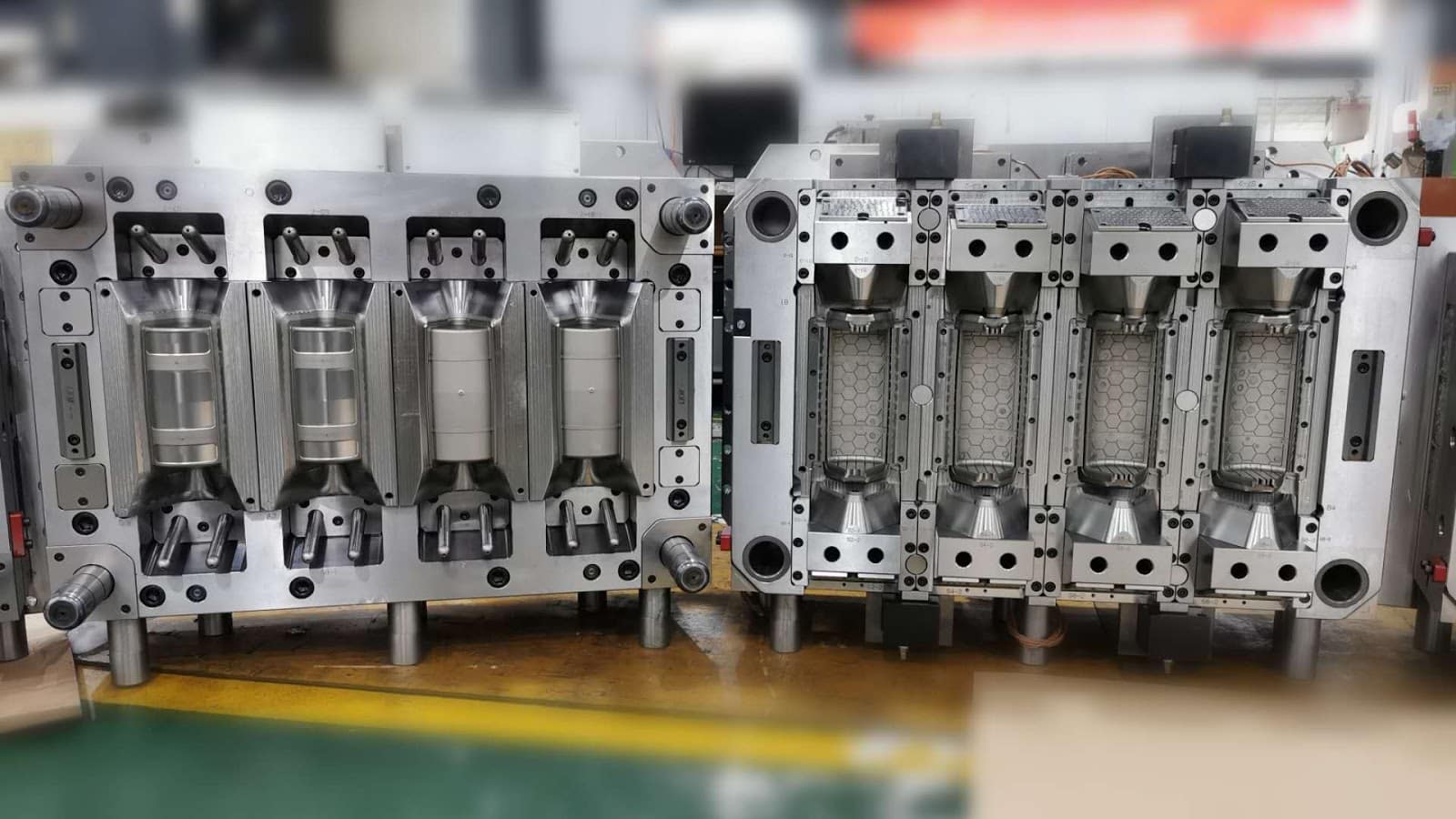

In the competitive landscape of manufacturing, where precision and reliability are paramount, Ironwood stands out as a beacon of excellence. With a legacy of innovation and a commitment to quality, Ironwood’s advanced plastic molds are setting new industry standards and redefining the possibilities of modern manufacturing. At the heart of Ironwood’s success is their unwavering dedication to technological advancement. The company has invested heavily in cutting-edge technology and state-of-the-art machinery, enabling them to create plastic molds that are not only durable but also remarkably precise. Their molds are crafted using advanced techniques that ensure each component meets the highest standards of quality and functionality. This commitment to technological excellence translates into superior products that consistently exceed client expectations. Ironwood’s plastic molds are distinguished by their exceptional versatility and adaptability. Whether you need molds for intricate, high-precision components or for larger, more robust parts, Ironwood has the expertise and resources to deliver.

Their molds are engineered to accommodate a wide range of applications, from automotive and aerospace to consumer goods and medical devices. This versatility is a testament to Ironwood’s ability to understand and meet the diverse needs of their clientele, ensuring that every project is completed with the utmost precision and efficiency. One of the key advantages of Ironwood’s plastic molds is their durability. Made from high-quality materials plastic injection molding companies and subjected to rigorous quality control processes, these molds are designed to withstand the demands of high-volume production. This durability not only reduces the frequency of mold replacements but also contributes to cost savings for manufacturers. By choosing Ironwood, clients benefit from a longer-lasting investment that delivers consistent, high-quality results over an extended period. Ironwood’s commitment to quality extends beyond the production phase. Their team of experienced engineers and technicians works closely with clients to understand their specific needs and provide tailored solutions.

This collaborative approach ensures that each mold is designed and manufactured to meet the exact requirements of the project, resulting in a product that is perfectly suited to its intended application. Furthermore, Ironwood places a strong emphasis on sustainability. The company is dedicated to minimizing its environmental impact through the use of eco-friendly materials and processes. By incorporating sustainable practices into their manufacturing operations, Ironwood not only contributes to environmental preservation but also supports clients in achieving their own sustainability goals. Acomold Ironwood’s advanced plastic molds represent a blend of innovation, precision, and reliability. Their commitment to technological advancement, versatility, durability, and sustainability makes them a preferred choice for manufacturers seeking superior quality and performance. With Ironwood, you are not just investing in a mold; you are investing in a legacy of excellence that ensures your products are manufactured to the highest standards. Experience the unmatched quality of Ironwood’s plastic molds and elevate your manufacturing capabilities to new heights.