3-way valves and gate valve systems play crucial roles in a variety of industrial and engineering applications, providing efficient flow control and enhancing system performance. These valves are widely used in sectors such as oil and gas, water treatment, chemical processing, HVAC, and automation. Their primary function is to control the direction and flow of fluids, gases, or steam, offering flexibility and reliability in complex piping networks. 3-Way Valves are often used in systems where the ability to control the flow of fluids in multiple directions is needed. These valves can either combine or divide fluid streams, depending on the system’s requirements. They typically come in three configurations: L-port, T-port, and multi-port designs. The L-port configuration is used to direct fluid from one inlet to one of two outlets, while the T-port configuration allows for a connection between all three ports, enabling switching between flow paths.

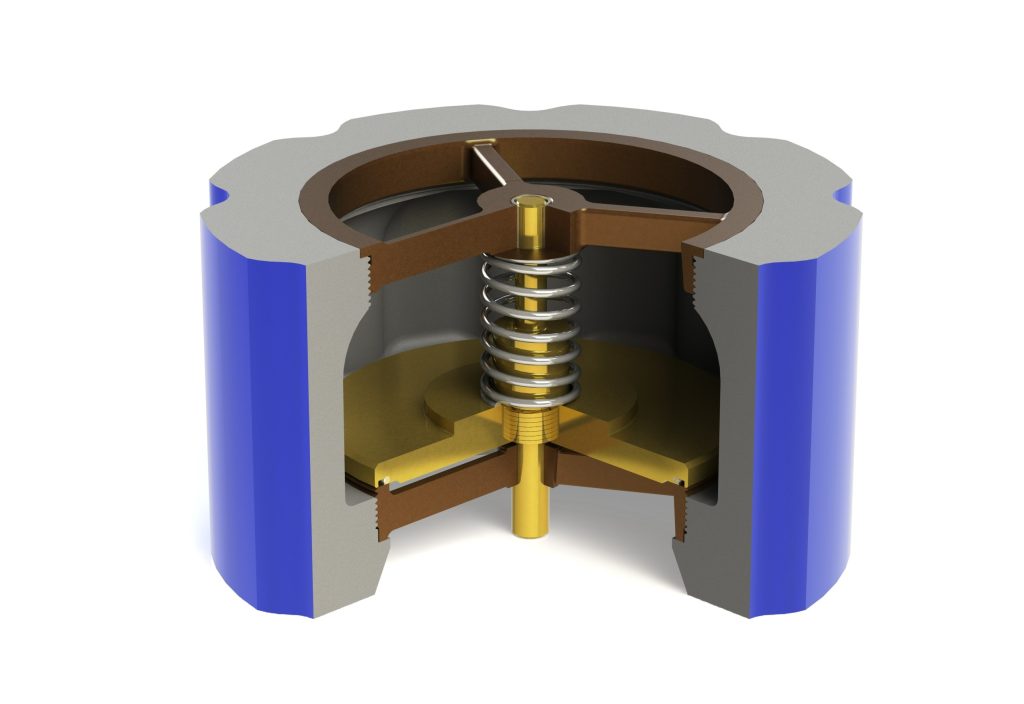

Multi-port valves are useful in situations requiring more complex routing of fluids. In HVAC systems, 3-way valves are vital for regulating the flow of heating and cooling fluids, ensuring precise control over temperature and energy usage. For instance, they are used in air conditioning systems to control the mixing of cold and hot water in heat exchangers. Additionally, these valves are employed in process control applications where they manage the distribution of gases or liquids across different sections of the process pipeline. Gate Valves, on the other hand, are primarily used in on/off applications, where full opening or closing is required. They are designed to allow or stop the flow of fluid with minimal pressure drop when fully open. 3 way valve are highly effective in systems where the valve does not need to be adjusted frequently and is required for large-scale flow control, such as in pipelines, water treatment plants, and oil refineries.

The smooth, linear motion of the gate valve ensures that the fluid flow is not restricted, and the seal formed when the gate is closed is robust, preventing leakage. Gate valves are most commonly found in systems dealing with slurries, large-scale water pipelines, and steam systems. Their straightforward design allows them to work efficiently even under high-pressure conditions, and their durable materials make them suitable for handling aggressive fluids. However, gate valves should not be used for throttling applications, as partial opening can cause damage to the gate valve diagram and the system. Both 3-way and gate valve systems are crucial for ensuring safety, reliability, and efficiency in many industries. Their designs cater to specific needs: 3-way valves provide flexibility in controlling flow direction, while gate valves excel at providing an effective on/off control in high-pressure environments. Together, these valve systems are indispensable in maintaining the stability and performance of industrial processes.